Cosmetic Mold Design Analysis for Cream Jar Lids

Discover how cosmetic molds for cream jar lids are designed and analyzed. Learn about the beauty-focused details important in making molds.

金型設計の要点:射出成形金型スライドの重要性

Have you ever wondered how intricate and complex features are seamlessly molded into plastic parts? The answer lies in the fascinating world of injection mold slides. These specialized components are the unsung heroes behind creating undercuts, threads, and other intricate details in molded parts. In injection molding, slides play a pivotal role in achieving what might seem impossible – producing complex parts without needing multiple molding steps. They move in and out of the mold cavity precisely, coordinating the formation of the desired shape. Speaking of which, understanding the different slide actions and components of injection mold slides is essential for achieving precision and consistency in the injection molding process. […]

射出成形金型のライフサイクルにおける効率と寿命の最大化

Have you ever wondered how long an injection mold lasts? It’s a tricky question with lots of factors at play. We can’t predict it perfectly, like we can’t predict when a car will break down. But we can estimate. This estimate helps us determine if a mold is doing well or falling short. Imagine a mold expected to handle 250,000 cycles but only manages 180,000. That’s a sign of falling short. Why? It could be how it’s used or issues with the mold itself. The key to making sure molds meet their expected cycles? It starts with picking the right mold maker. A good one helps you care for your […]

精密成形のための金型サイドアクションをマスターする

Amidst the evolving global markets and shorter product life cycles, mold design faces escalating challenges, and mold side action emerges as a strategic solution, especially when dealing with intricate part geometries or challenging undercuts. Understanding these scenarios forms the foundation for harnessing the full potential of mold-side action. This article delves into the intricacies of side action in injection molding, lateral mold movement, and off-center mold motion, empowering mold makers, designers, molders, and manufacturers with the knowledge to make informed decisions. As industry demands evolve, the ability to seamlessly implement mold-side action becomes an invaluable skill set. But don’t worry; we’re here to simplify the complexities for you, providing actionable […]

金型シャットオフの解読:設計と機能の総合ガイド

Amidst the ever-changing realm of injection molding, it’s crucial to delve into the nuances of mold design. Mold shut-offs, often overlooked but crucial, take center stage to tackle challenging tooling and design hurdles. Think of them as the masterminds working backstage, skillfully coordinating the production of intricate part features with finesse, all without the hassle of post-molding adjustments. But that’s certainly not enough info to better use, implement, and adjust mold shut-offs in injection molding. Hence, this article will take you through everything related to mold shut-offs to help you better understand and decode this crucial component in injection molding. So please keep reading to learn all about it! Understanding […]

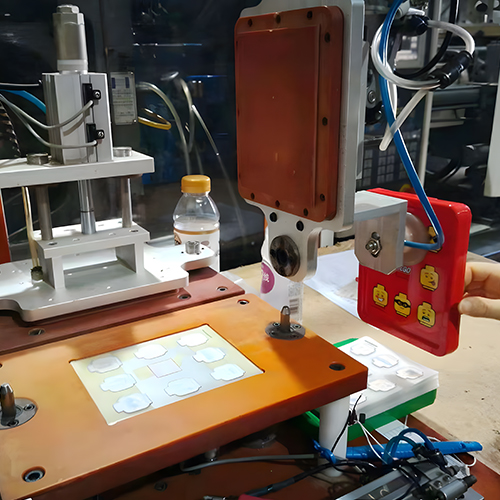

インモールド・ラベリングのプロセス

Prototoolでインモールドラベリング(IML)を体験してください。

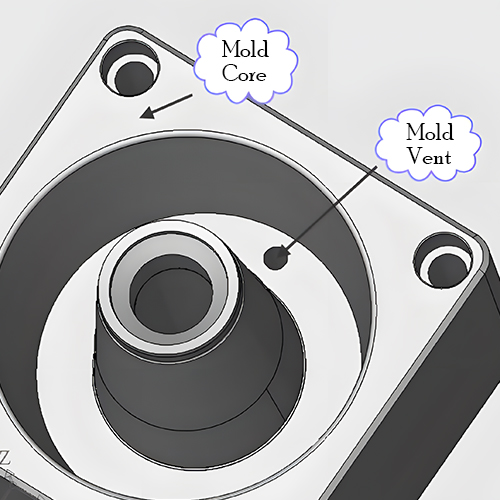

射出成形におけるベントの場所と方法

Learn strategic mold venting placement, methods, and design tips to improve part quality, protect molds, and boost efficiency with Prototool.

射出成形金型の効果的な修理のための重要なヒント

射出成形金型を修理するタイミングと方法、重要なメンテナンス・パラメーター、8ステップの修理ガイド、4大メリットをご紹介します。

ベリリウム銅射出成形金型の特徴:最も高価な金型材料の用途

高価だが貴重な素材であるベリリウム銅射出成形用金型の卓越した品質をご覧ください。

射出成形金型受入基準

金型の受入基準に関するガイドをご覧ください。金型または製品の関係者のために、最高の品質と機能性を確保する方法をご覧ください。