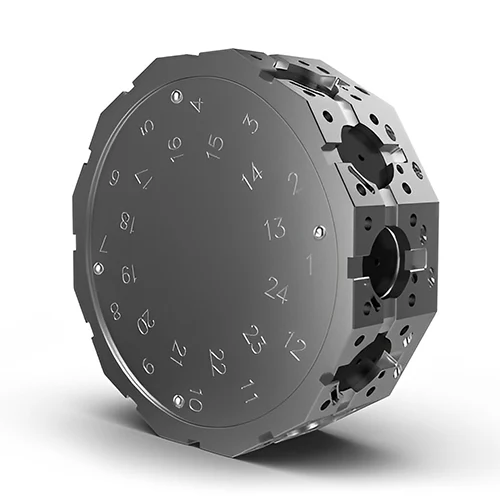

CNCマシンの工具タレットについて知っておくべきすべて:

Are you struggling to understand what a tool turret is? Simply put, indexing tool carriers for lathes, transfer machines, and other CNC machine tools are known as tool turrets. They enable equipment to carry numerous cutting tools simultaneously and mount individual tools properly. These tool turrets can replace a manual tool post or rotary indexer, increasing processing efficiency and lowering setup costs. Understanding the working and performance of a tool turret helps operate a CNC machine for part production more efficiently. In this article, we will study what a tool turret is, how it functions, and what can happen if it is not maintained during CNC machining processes. Suggested: 6 […]

効率的なCNC加工に切削油剤が重要な理由とは?探ってみましょう!

During CNC machining, the nozzle near the cutting area ejects an oil-like liquid called cutting fluid. This cutting fluid is a lubricant used in CNC machines for lubrication, cooling, and cleaning. As a result, cutting fluid is crucial in CNC machine automatic machining. Now let’s explore cutting fluid, its types, and uses. This article will also explore the tips for picking the right cutting fluid for manufacturing. So stay tuned! Related: CNC Thread Machining 101: What It Is and How It Works? What is a Cutting Fluid? Cutting fluid is a type of industrial liquid used in metal cutting operations such as CNC machining to lubricate and cool the cutting […]

CNCスレッド加工101:それは何であり、どのように動作しますか?

ねじの加工品質と加工効率は、部品の加工品質、ひいてはマシニングセンタの生産効率に直接影響し、CNC加工性能の進歩に伴う。そのため、切削工具やねじ切り加工方法の進歩は絶えず進み、ねじ切り加工の精度と効率は着実に向上している。CNCマシニングセンタで実際に一般的に使用されているいくつかのねじ切り加工方法は、このCNCねじ切り加工に関する詳細なブログにまとめられています。もしあなたが、加工におけるねじ加工方法の選択、生産効率の最適化、品質事故の低減に苦慮している技術者であれば、私たちがあなたをサポートします。CNCねじ加工のすべてを学ぶために読み続けてください。こちらもお読みください: [...]

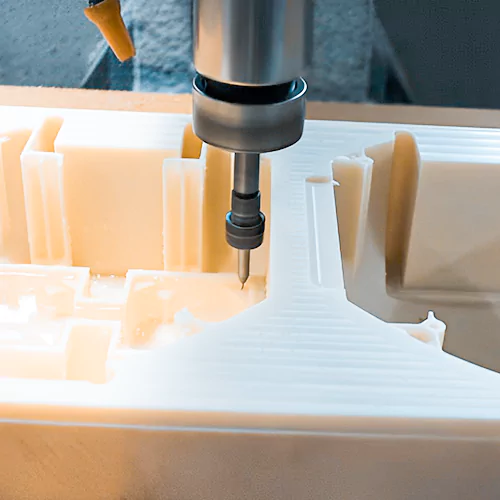

なぜCNCプロトタイピングを検討すべきなのか?使用の必要性、限界、専門家のヒント

Precision and adaptability are hallmarks of CNC prototyping, and the many available materials and CNC machines only add to these properties. However, understanding the usage of CNC prototyping and how you can do it effectively is just as important as understanding the basics of this machining procedure. If you’re unfamiliar with how it works and how to effectively manage CNC prototyping for producing effective prototypes, it may be challenging to deliver quality products in a manufacturing business. But don’t worry; we’ve got you covered with this detailed guide on CNC prototyping and when you should implement this machining process. What is CNC Prototyping? Prototype machining is a procedure that uses […]

CNC機械加工プロジェクトで考慮すべきステップ

あなたがCNC製造会社を経営しているにせよ、こうしたCNC機械加工サービスに投資しているにせよ、CNC機械加工プロジェクトの処理に関わる段階を理解することは非常に重要である。材料の準備から加工、CNCマシンのプログラミング、生産品質の監視、製品またはプロジェクトの最終仕上げの制御まで、いくつかの段階がCNC機械加工タスクの完成を支援する。この詳細なエッセイでは、CNC機械加工プロジェクトの加工手順について説明する。CNC機械加工プロジェクト加工のための5ステップガイド材料の準備CNCマシニング加工の材料準備は、完成品が必要なパラメータと一致することを保証するために非常に重要です。ここでは、CNC機械加工用の材料を準備するためのステップバイステップガイドをご紹介します。

How to Choose the Best CNC Machining Company for Your Products?

Are you looking to invest in a budget-friendly, quality-focused, and reliable CNC machining company? Picking the right company for your product parts machining is a critical task. However, with endless CNC machining companies available today, which one do you choose? Companies specialize in different areas of CNC machining tasks in the CNC machining industry. Hence, understanding your product’s machining needs and how you can pick a company that fulfills this need is crucial. In this comprehensive guide, you will find an exploration of all the factors that require consideration when making this decision. 6 Things to Consider When Choosing a CNC Machining Company: The following are the essential considerations to […]

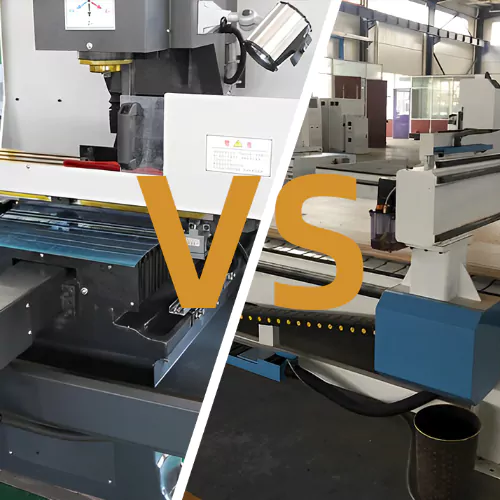

CNC Mill vs. Router – Comparing Speed, Function, Accuracy, Cost, and More!

According to Fortune Business Insight, the global CNC machine market was estimated to be worth USD 83.99 billion. This market is further expected to grow to USD 140.78 billion by 2029. That said, CNC machines are common automated machines manufacturers use to process materials and create diverse products. But how do you know which CNC machine suits your product’s production demands? Specifically, common machines like CNC routers and CNC mills help make manufacturing tasks easier and more efficient. For choosing one of these machines, it’s important to understand their differences and cost estimates. In this guide, we will discuss a detailed comparison between CNC mill vs. router and how these […]

6 Common Challenges Faced by CNC Manufacturing Companies

The increased need for better efficiency in complex machining goods by sectors is projected to impact the growth of the CNC manufacturing industry. Yet, the growing demand for high precision and lower operating costs, as well as technological developments in manufacturing processes, are all impacting the appeal of CNC technology. However, the spike in mass manufacturing of items across industry verticals, including automotive and electronics, is responsible for the expansion of the CNC (Computer Numerical Control) machine market. Increased demand for mass customization is also driving the adoption of these technologies. So what are the risks associated with this market and its possible manufacturing business model? Is this market capable […]

Types of CNC Machines – The Types and How They Work

Starting a business that produces CNC parts? While funding can be the only requirement to launch a manufacturing enterprise, numerous other considerations exist. Familiarizing yourself with the types of CNC machines available for producing high-quality parts is critical. Additionally, CNC machines employ distinct materials to produce intricate and accurate parts. If you lack knowledge about the various types of CNC machines and their operations, let’s explore the different kinds of CNC machines in detail, including their applications, components, and mechanisms. Types of CNC Machines – A Detailed Analysis of Their Structure and Working Different types of CNC machines used in the production industry today have different components and working criteria. […]

CNC Milling Parts: What Factors Can Cause The Deformation?

CNC milling is a highly precise and efficient manufacturing process that produces complex and accurate parts. However, despite its precision, CNC milling parts can sometimes experience deformation, resulting in defective parts that do not meet the required specifications. This deformation can occur due to various factors that affect the machining process, such as material properties, cutting parameters, machine stability, and environmental factors. In this article, we will understand the common factors that can cause CNC milling parts deformation, the effects of this deformation on the final product, and ways to prevent it. By understanding these factors, manufacturers can take steps to ensure the production of high-quality, accurate parts that meet […]