The Five-Axis Machining Process of the Heat Dissipation System for Signal Stations

Turning up the cool factor: Crafting a hip heat-busting gizmo for signal stations out of aluminum!

Is This the Prototype of the Beijing Olympics Venue, the ‘Bird’s Nest’? Or Just Nest-algia

⚙️A close-up of the impeller machined by the 5-axis machine.💡🤔Is this a prototype for Nest-type Beijing Olympic Stadium? Can you guess what material this is made of?

CNC Machining Milling Turning Parts At Prototool

Check out the CNC factory’s CNC machining and milling & turning parts from the Pearl River Delta in China.

Titanium Machining For Top-Quality Parts: Insights On Properties, Techniques, And Beyond!

Familiarize yourself with top-tier titanium machining facilities and the operations of a good processing plant specialising in metal parts.

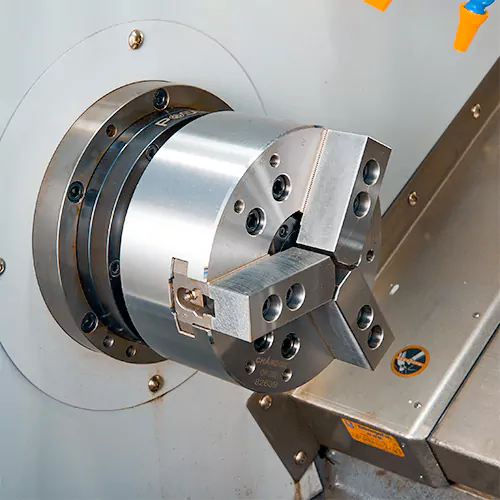

Main Spindle In CNC Machines: Definition, Function, Types, & Buying Guide

Did you know every CNC machine has a computer numerical control spindle at its core? The spindle is a crucial machine part, yet most people don’t consider it. A CNC router, engraver, or lathe might have one. The CNC spindle has a significant impact on machine tool performance. Understanding the spindle mechanism is critical when deciding which spindle to use. In this article, we will discuss what a CNC spindle is and how it works on machine tools, the types of CNC main spindles, and a short guide to selecting the proper one. What is the Main Spindle in a CNC Machine? In a CNC machine, the primary spindle is […]

How Does a CNC Tool Lifter Work?

A lifter moves at an angle during ejection to remove steel from undercuts or details inaccessible to slides or other mechanisms. This component has different names and design variations. Lifter design, angle, and materials can all have a significant impact on tool performance over time. Now let’s go ahead and explore all about a CNC tool lifter below in detail. Suggested: CNC Machine Tools: Choosing the Right Tool for CNC Machining A Detailed Overview of CNC Tool Lifter: A CNC lifter, also known as a tool lifter or tool changer, is an essential component in CNC (Computer Numerical Control) machines. It is responsible for automatically changing and exchanging cutting tools […]

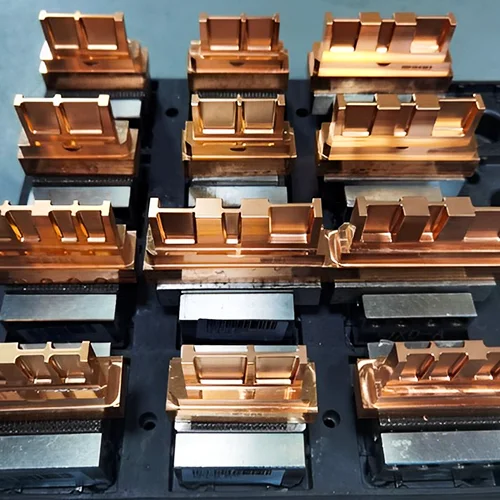

Comparing Electrode Machining Process on Different Materials: How It Works?

Electrode machining is among the newer metal processing techniques, compared to rotating cutters, shearing, and forging. This machining process passes rapidly pulsed high-voltage electrical discharges (sparks) across the gap between the electrode and the grounded workpiece. As a result, it helps remove the material from the workpiece by erosion. This way, even the most complex and intractable material can be cut and machined with very little bulk heating and virtually no application of macro forces, provided that the material is electrically conductive. This results in very low distortion and no addition of meaningful residual stresses to the workpiece. But wait! Why should you opt for electrode machining for your production […]

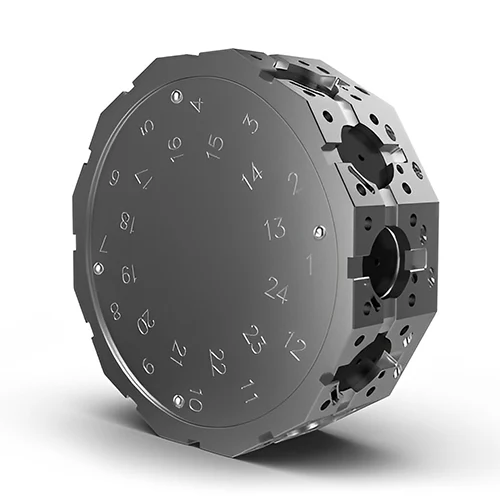

CNCマシンの工具タレットについて知っておくべきすべて:

Are you struggling to understand what a tool turret is? Simply put, indexing tool carriers for lathes, transfer machines, and other CNC machine tools are known as tool turrets. They enable equipment to carry numerous cutting tools simultaneously and mount individual tools properly. These tool turrets can replace a manual tool post or rotary indexer, increasing processing efficiency and lowering setup costs. Understanding the working and performance of a tool turret helps operate a CNC machine for part production more efficiently. In this article, we will study what a tool turret is, how it functions, and what can happen if it is not maintained during CNC machining processes. Suggested: 6 […]

効率的なCNC加工に切削油剤が重要な理由とは?探ってみましょう!

During CNC machining, the nozzle near the cutting area ejects an oil-like liquid called cutting fluid. This cutting fluid is a lubricant used in CNC machines for lubrication, cooling, and cleaning. As a result, cutting fluid is crucial in CNC machine automatic machining. Now let’s explore cutting fluid, its types, and uses. This article will also explore the tips for picking the right cutting fluid for manufacturing. So stay tuned! Related: CNC Thread Machining 101: What It Is and How It Works? What is a Cutting Fluid? Cutting fluid is a type of industrial liquid used in metal cutting operations such as CNC machining to lubricate and cool the cutting […]

CNC旋盤主軸台:詳細ガイド

The CNC lathe machine headstock plays a vital role in machining, serving as the powerhouse that drives rotation and securely holds the workpiece. A geared transmission that supplies power and rotation to various lathe components is known as a CNC lathe headstock. Let’s explore the definition, design, and function of the CNC lathe headstock. Suggested: Types of CNC Machines – The Types and How They Work What is a CNC Lathe Headstock? The CNC lathe machine headstock is a vital and integral part of the overall machine structure. Positioned at the left end of the lathe bed, it serves as the central hub for the rotational movement of the workpiece […]