優れたCNCオペレーターに必要なスキルとは?

Have you ever encountered a complex problem in the store where no one seemed to know what to do, and someone stepped forward and rescued the day? Such situations are what raise certain employees above others in the workplace. They can result in promotions and pay hikes. Nothing beats saving the day because you have rare expertise or skill and no one else to turn to. If this sounds like a lovely situation that will help you get some nice points from your supervisor at work, it’s time to make it a reality. How do you go about doing that? It’s easy! As a CNC operator, you must ensure that […]

CNCプロトタイプ:製品加工のファーストチョイス

Generally speaking, a CNC prototype is employed for design assessment, functionality testing, quality assurance, idea iteration, and design enhancement. Producing rapid, inexpensive prototypes that can be carefully scrutinized before moving on with mass production provides insightful information into a prototype product concept. Because hard tooling is not required, rapid prototyping may be completed relatively quickly. One of the best methods for quickly producing prototypes is CNC machining. Using this method, you may provide high-quality prototypes in the shortest possible time by utilizing computer numerical control. If you’re wondering how to make a prototype and more? Here are a few additional reasons why CNC machining should be your preferred method for […]

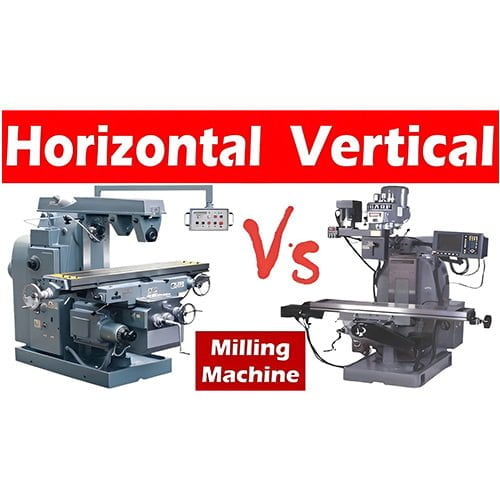

横フライスと縦フライスの比較 - 究極のガイド

In the industrial sector, milling machines are often used to shape hard metal or to manipulate extremely big items. Milling is a common machining method that includes removing material from a stationary workpiece using a rotating cutting tool. They may be horizontal milling or vertical milling, and each has a unique operating characteristic that makes them suitable for certain operations and activities. This article examines the primary differences between horizontal and vertical milling machines, the uses for each kind, and the advantages and disadvantages of using each. Although all milling machines perform the same fundamental function, some are more suited for particular tasks than others, and their operations vary. What […]

CNC精密加工:これからの時代に最適な加工方法

CNC precision machining is a remarkable service that enables the production of bespoke CNC machined components to an extremely high degree of accuracy. Hence, high-precision CNC machining is highly impactful and efficient in production processes. Today, plenty of manufacturers and companies prioritize the presence of this machining process in any production, making it a modern-day essential in the manufacturing industry. However, despite its growing demand, many individuals contemplating upgrading from manual machines don’t know what each phrase means or the advantages of employing a precision CNC machine product tailored to their specific requirements. But since precision manufacturing is often linked with high-end production, it is undoubtedly the need of the […]

CNCプロトタイプ加工:その種類と用途

Are you looking for a prototype manufacturing method for your products or business? Opting for prototype CNC machining for such manufacturing demands can be an ideal approach. Moreover, professional manufacturers and technicians offering reliable CNC prototype machining services can be an ideal option at times like these, whether you need small-scale or batch prototype production. But is that enough, or should you also be familiar with the process and how it works? Undoubtedly, it’s the latter since gaining awareness not only adds to how you want to proceed with the prototype process but also makes it easier to proceed with a process that meets your product requirements. Besides, with the […]

アルミニウム加工:最も一般的なアルミニウム合金の種類

アルミニウムは間違いなく、現代世界の能力開発に貢献した最も広く利用されている金属の一つです。アルミニウム合金は、多種多様な需要のある製品の製造を可能にします。アルミニウム合金は、加工が最も簡単な材料の一つであるため、アルミニウムの機械加工など、幅広い産業で多くの用途に選ばれています。その優れた加工性に加え、アルミニウムは、迅速なプロトタイプの製造から精密なアプリケーションの実行に至るまで、幅広いニーズを満たすのに適した膨大な数の合金と等級で利用可能です。CNC 否定することは不可能である。

CNC治具:種類と正しい選び方

Are you considering the usage of a CNC machine for your production demands? Whether you’re familiar with a CNC machine or opting for it for the first time, understanding the machine and its tools is essential to achieve efficient production outcomes. In addition, you can’t make or give production decisions to your processing manufacturer, like Prototool, without being familiar with what you need. Hence, a CNC machine comprises various tools. Each of these tools is used in different capabilities and production requirements. So, if you’re unaware of how they work and what outcomes they provide, making effective production/customization decisions can be challenging. This article will cover a detailed guide on […]

放電加工:さまざまなアプローチと利点

放電加工は、従来の機械加工技術には多くの欠点があったため、企業にとって実行可能な選択肢として浮上してきました。熱エネルギーを使用する放電加工は、ワークピースから余分な材料を除去する信頼性の高い効果的な方法です。製造業者は、この方法を使用して、他の方法では製造が困難または不可能なアイテムを作成します。非常に要求の厳しい加工用途では、放電加工が解決策であり続けます。エンジニアは、従来の手順では困難または不可能な状況でも、材料を加工することができます。この独特な手順により、高品質の部品が製造される。放電加工は、自動車、電子機器、航空宇宙、製薬、食品・飲料、スタンピング、防衛など、多くの分野で使用されています。この記事では、放電加工について説明する。

CNC Machining Tolerances: Everything You Need to Know In 2023

A CNC or Computer Numerical Control is a machining method. In the CNC machining method, the CNC machining tolerances play a vital role in determining how the machine variables can be changed per different production demands. Typically, a CNC machine comprising computer programming and electromechanical devices automates metal and non-metal parts as per those parts’ automation and production demands. Additionally, these machines ideally conduct all the operations involved in the metal and non-metal products production/automation as per the program and its parameter tolerances to create a final and usable product. Using a CNC machine is common in today’s industrial and manufacturing industries. However, it’s crucial to understand the CNC machining […]

CNC machining aerospace parts: the Most Popular Processing In Production

The aerospace industry encompasses the research, development, and manufacturing of an array of aircraft and spacecraft products, such as commercial and military aeroplanes, helicopters, and gliders, as well as spacecraft, launch vehicles, satellites, and other space-related objects. Flying in the earth’s atmosphere is not as easy and simple as moving on the ground. Whether for commercial air travel, space aviation, or the defence sector, the quality and durability of aerospace parts and structures must be taken into account. It needs the utmost skills and ability to produce complex geometries of aircraft parts with high precision. There is no room for human error. This is where CNC machining Aerospace parts come […]