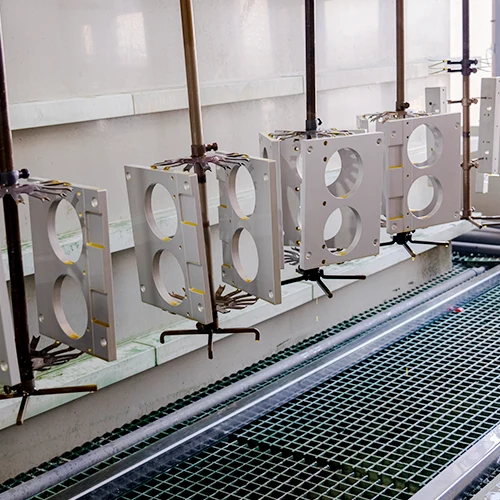

Metal Anodizing CNC Machined Parts – A Brief Guide

Metal anodizing is a popular technique in the engineering and maker communities. It’s well-known for improving the strength, durability, and lifetime of machined components, making it a vital technique in the manufacturing process. Aside from these advantages, anodizing has several advantages that make it important for producing high-quality parts. Anodizing should be a top priority […]

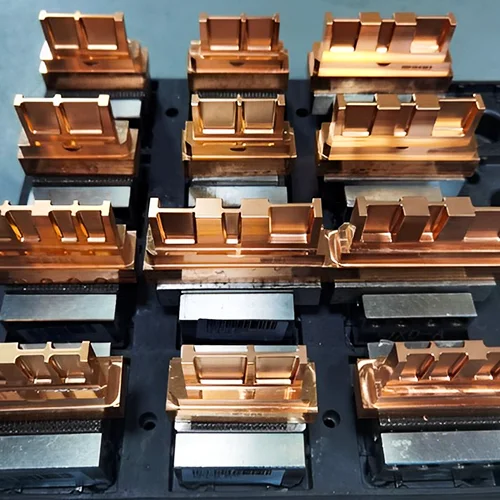

Comparing Electrode Machining Process on Different Materials: How It Works?

Electrode machining is among the newer metal processing techniques, compared to rotating cutters, shearing, and forging. This machining process passes rapidly pulsed high-voltage electrical discharges (sparks) across the gap between the electrode and the grounded workpiece. As a result, it helps remove the material from the workpiece by erosion. This way, even the most complex […]

Why Is Cutting Fluid Important for Effective CNC Machining? Let’s Explore!

During CNC machining, the nozzle near the cutting area ejects an oil-like liquid called cutting fluid. This cutting fluid is a lubricant used in CNC machines for lubrication, cooling, and cleaning. As a result, cutting fluid is crucial in CNC machine automatic machining. Now let’s explore cutting fluid, its types, and uses. This article will […]

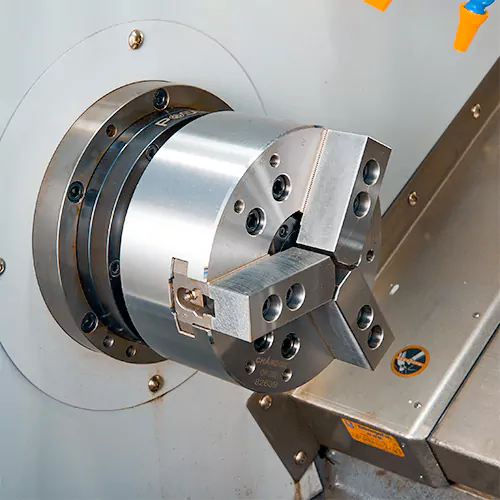

CNC Lathe Headstock: A Detailed Guide

The CNC lathe machine headstock plays a vital role in machining, serving as the powerhouse that drives rotation and securely holds the workpiece. A geared transmission that supplies power and rotation to various lathe components is known as a CNC lathe headstock. Let’s explore the definition, design, and function of the CNC lathe headstock. Suggested: […]

CNC Thread Machining 101: What It Is and How It Works?

The machining quality and efficiency of the threads will directly impact the machining quality of the parts and, consequently, the machining center’s production efficiency with the advancement of CNC machining performance. Therefore the advancement of cutting tools and threading methods is continually increasing, and threading accuracy and efficiency are steadily improving. Several thread processing methods […]

Steps to Consider When Processing CNC Machining Projects

Whether you own a CNC manufacturing company or are an investor in these CNC machining services, it is critical to understand the stages involved in processing CNC machining projects. Several phases assist complete CNC machining tasks, from preparing materials to processing them, programming the CNC machine, monitoring production quality, and controlling the final finishing of […]

6 Common Challenges Faced by CNC Manufacturing Companies

The increased need for better efficiency in complex machining goods by sectors is projected to impact the growth of the CNC manufacturing industry. Yet, the growing demand for high precision and lower operating costs, as well as technological developments in manufacturing processes, are all impacting the appeal of CNC technology. However, the spike in mass […]

The Most Common Types of Machining Services and Processes

Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the most common types of machining methods, […]

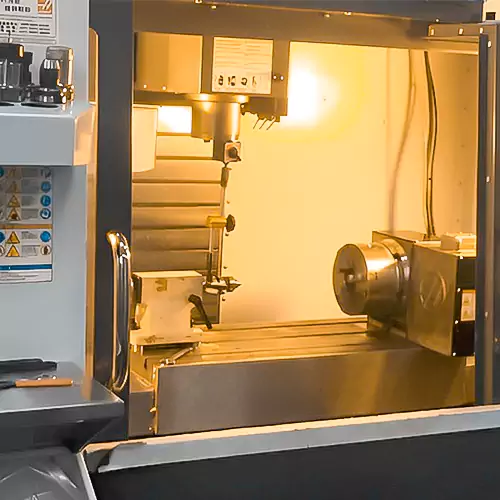

4-Axis CNC – The Various Features and Important Details About It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. […]

High Speed Machining: What it is & How to Use it?

So, what exactly is high speed machining? It achieves a high metal removal rate by combining lighter milling passes with high spindle speeds and feed rates. High-speed machining reduces cycle time, extends tool life, and boosts shop productivity. If you’re ready to start a high-speed machining operation in your shop, here are some things to […]