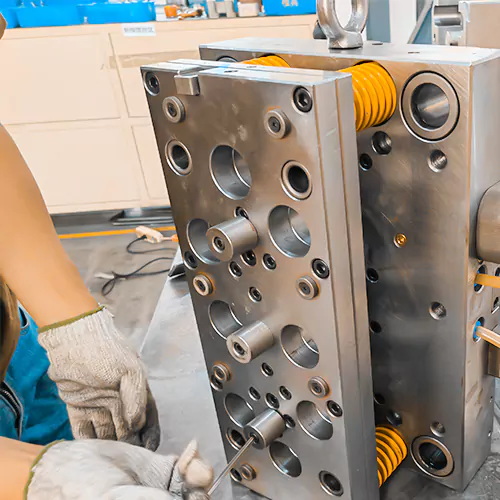

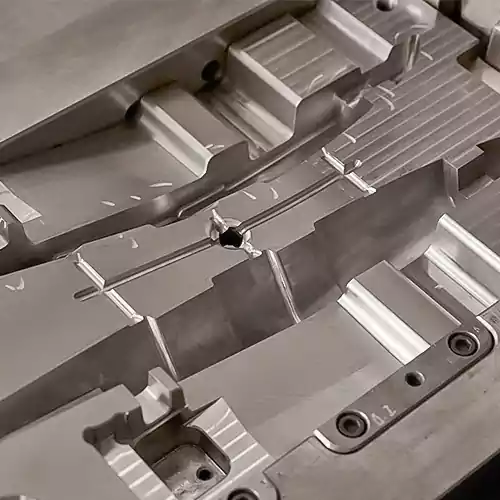

The complete introduction of mold parts

Injection molding is primarily a phenomenon in the manufacturing processes of plastic. It is a manufacturing process that involves shaping a liquid or malleable raw material with the help of a fixed frame, also known as a mold or a matrix. A mold is a hollow cavity receptacle, usually made of metal, into which liquid […]

How to Maintain Tool and Die?

During their daily operations, manufacturing sectors extensively use various instruments to ensure that they can produce a large number of items. They use a cutting tool and die, one of the instruments in their toolkit. A machine tool can mold work pieces into a profile or shape as a cut or die. Cutting dies can […]

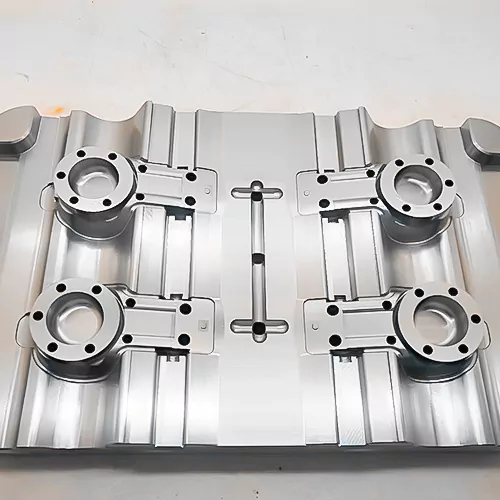

Aluminum Injection Molds: How Does It Work For Product Manufacturing

Traditional injection molding procedures are time-consuming and labor-intensive because they rely heavily on physical labor. This not only increases production time but also increases labor costs and leaves room for human error. It leads to quality problems, which can contribute to manufacturing delays. In comparison, the modern aluminum injection molding technique by aluminum injection molds […]

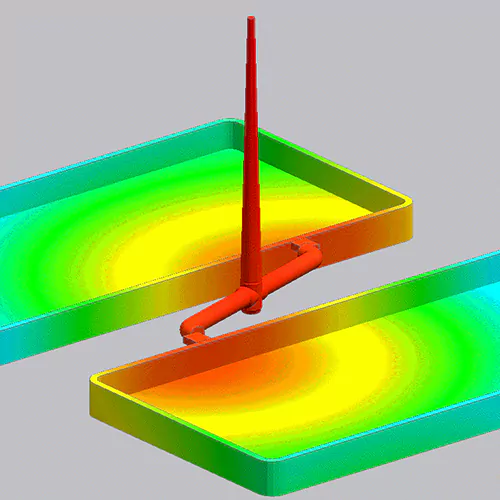

Mold Flow Analysis: What Is It And Complete Details

When it comes to tooling, there is no room for error in the smallest of details. However, with the large number of factors that have the potential to influence production, it’s easier to avoid mistakes if you are fully aware of every process and its detail. Speaking of which, mold flow analysis is a critical […]

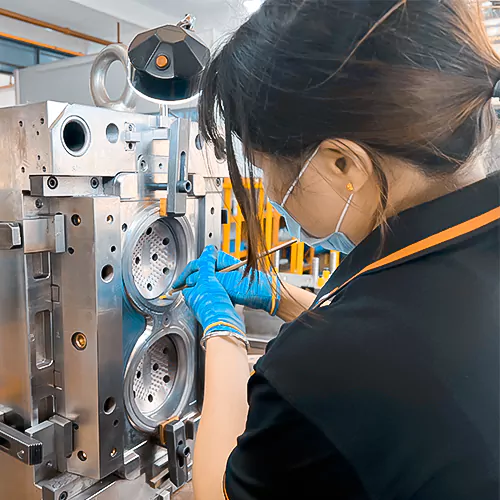

Mold Polishing: An Important Step In Mold Making Process

Products made of plastic for industry and commerce are currently getting better and more varied. As a result, it is up to producers to raise the caliber of molds. It is due to the direct role that molds have in determining the quality of a product. Plastic injection mold polishing became necessary as a result […]

What Are The Features Of Precision Injection Molds?

The goal of precision injection molding and injection molds, a highly technical technique, is to produce exact plastic components with complex geometries for a variety of industrial applications. Precision injection molding is never utilized to produce whole items. Precision molds, which are essential to the process and which need to be carefully designed and made, […]

Rapid Injection Molding: Differences from conventional injection molding

Rapid injection molding is essential as the “digitization” of practically every manufacturing process proceeds. Molding is the most recent industry to witness this transition. Here’s how traditional molding service providers may be affected by digitization. Digital manufacturing provides numerous advantages across various touch points, including reduced time to market, labor expense, asset utilization, and improved […]

Molds For Plastic Injection: The Most Basic Guide

For the manufacture of tiny, medium, and large-sized plastic parts, molds for plastic injection is the most often utilized manufacturing technique. An injection molding machine, unprocessed plastic, and a mold are all used in the procedure. After being heated to molten plastic in the machine, the plastic will be injected into the cavity, where it […]

Ejector pin In injection molding: Detailed overview of the types

When ejector pins in injection molding were introduced to industrial processes, it sped up production, automated procedures, and produced higher-quality goods. Additionally, it has helped make product designs more uniform. The injection molding method still has many issues that need to be fixed, like ejector pin marks, even though it has improved manufacturing procedures. This […]

Injection Mold Delivery Time: The Answers to People’s Concerns Are Right Here

Injection mold — the principal tool that handles the injection molding process, where you inject plastic material into this mold tool. Once it cools and hardens to the cavity configuration, you get a plastic injection molded product. Today, injection molding technology is best employed to mass-produce highly accurate and frequently complicated end-use parts. 3D printing […]