A Step-By-Step Guide on The Injection Mold Lifter Design

Designing a lifter for injection molding is a complex and technical process that requires careful consideration of many factors. A lifter is a small, movable component used to lift the molded part off the core side of the mold during ejection. It is a critical component in injection molding because it helps create complex geometries […]

Key Injection Mold Components You Should Be Familiar With

If you’re planning to produce a plastic part using injection molding, you’ll need to familiarize yourself with the essential injection mold components. From the sprue to the sub-runner and exhaust port, each component plays a vital role in the injection molding process. However, if you’re new to injection molding, you may find yourself lost in […]

Gas-Assisted Injection Molding: Innovative Plastic Manufacturing Solution

In today’s fast-paced world, the manufacturing industry is one of the most innovative, always setting new norms. In this growing and evolving industry, gas-assisted injection molding is an innovative plastic manufacturing technology that produces high-quality products. Today, we will dive further into the manufacturing process by discussing what it is and its various types, applications, […]

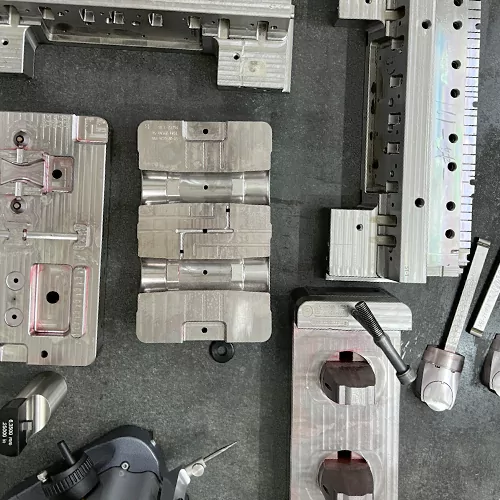

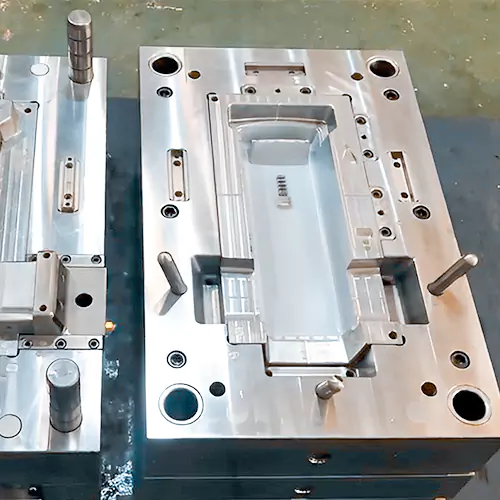

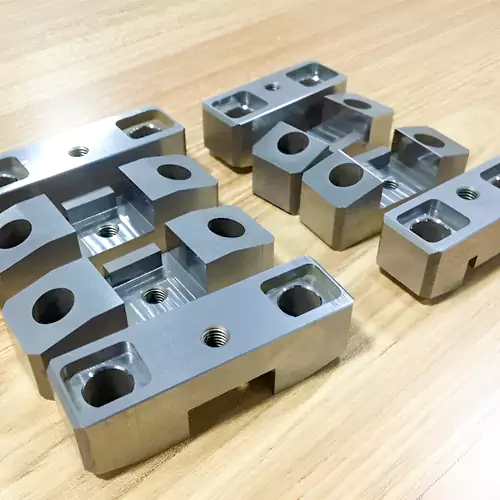

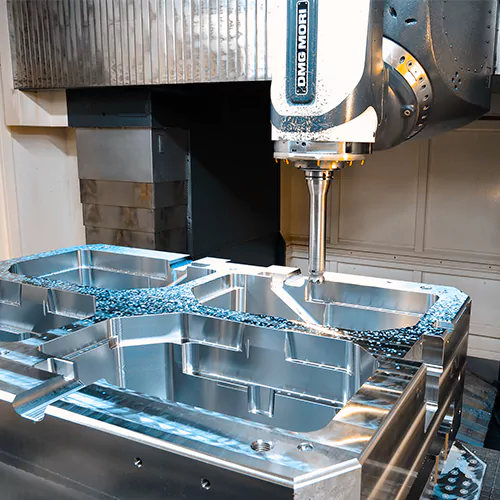

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. This article will […]

High-Quality Plastic Injection Mold: How You Can Enhance Mold Quality?

Are you curious how you can better manufacture high-quality plastic injection mold? The global plastic injection molded parts market is now worth $325 billion, with a 5.7% increase expected through at least 2025. Considering this growing adoption, it’s evident that one of the most notable advantages of plastic injection molding is the ability to produce […]

Plastic Products Supplier Prototool: “Specialized in Special Engineering Material Applications”

Are you looking for a trusted plastic products supplier for your business? Whether in the beauty industry or other grossing business markets like automobile, electronics, consumer products, aerospace, etc., plastic products are used in every industry today. From medical products and supplies to beauty boxes, makeup product containers, furniture, and other products used in our […]

8 Tips to Reduce the Cost of a Plastic Injection Mold

When it comes to producing plastic components for various uses, one of the most widespread methods is known as plastic injection molding. Manufacturers need a plastic injection mold designed according to the product that needs to be produced. Now a typical question asked by those looking for a manufacturer is, “How much will the plastic […]

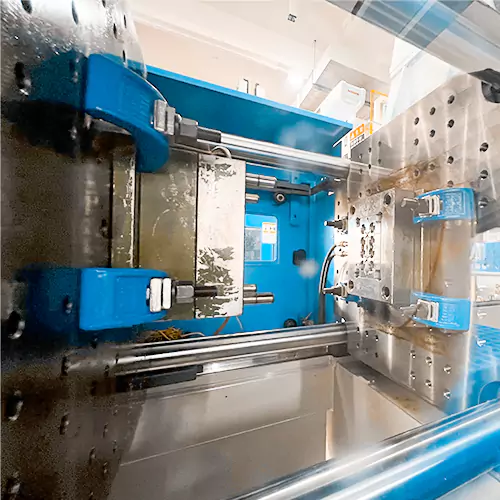

The 101 of Plastic Injection Molding Service from China

Plastic injection molding service is widely utilized for producing plastic parts of varying sizes. One needs a mold, some unprocessed plastic, and an injection molding machine to complete the procedure. The plastic is heated to the melting point in the machine, injected into the mold, and allowed to cool and harden. Products from the automotive, […]

What are the Differences Between General CNC Machining and Precision Machining

Manufacturing is one of the world’s largest industries in today’s automated world. Manufacturing is found worldwide, from the United States to Indonesia, France, Germany, and many other countries. As a result, our daily needs, such as vehicles, medicines, clothing, and much more, continue to be met in various parts of the world each year by […]

Die Tooling: The most commonly used processing equipment and processes

Being a fabrication process, die cutting uses specialized equipment and machine tools to cut, mold, and shear stock material into unique forms and designs. The die-cutting method is versatile and adaptable to various materials, including metal, plastic, wood, and composites. It is also used in various sectors for die-cutting neoprene, gasketing, paper, packing, die-cutting cloth, […]