Sprue Bushing of Plastic Injection Mold: What You Should Know?

If you’re new to the world of injection molding in the production industry, the term ‘sprue bushing’ may confuse you. Simply put, it’s a component used in injection molding machines that plays a vital role in production. But there’s more to exploring how sprue bushing works and what should be considered to ensure the best […]

Mold Core: What It Is and How Is It Different From a Mold Cavity

Rapid injection molding has the purpose of producing parts quickly. Proper design aids in ensuring that good parts are generated on the first run. Consequently, it is necessary to determine how the item will be put in the mold. The most important consideration is that the part remains in the mold half containing the ejector […]

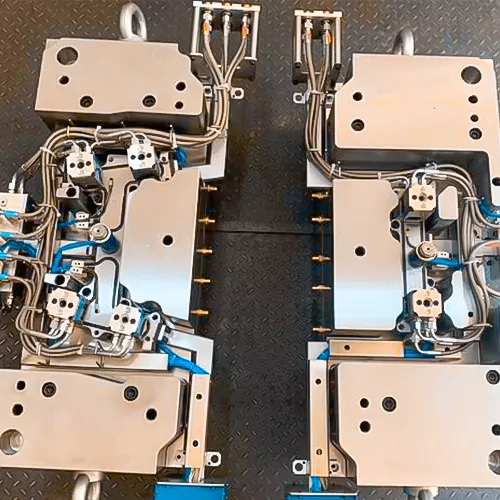

A Brief Guide on Designing The Hot Runner Plate in Injection Molding

The hot runner plate has defied tradition in the plastic injection molding industry since its conception in the 1960s until its acceptance in the 1990s. Hot runners appeal to many who want to diversify their injection molding process due to their enhanced cycle speed and decreased waste. However, it can be tricky to design and […]

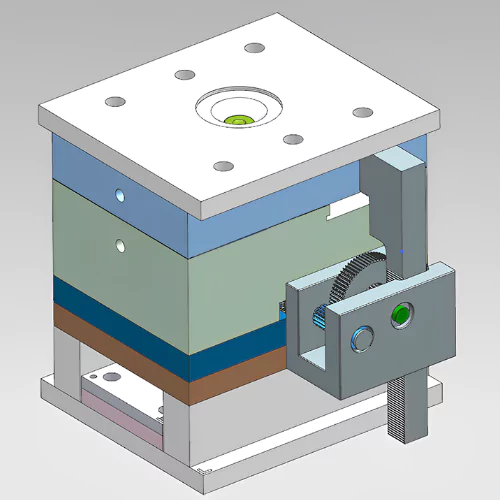

Unscrewing Mold 101: What It Is, Working, Importance, and More

The unscrewing mold is one of the most interesting varieties of injection mold. Because of their commonplace nature, you might assume that carefully considering the necessary design is unnecessary. Now let’s dive in and find out what this type of mold is, what we should keep in mind when working with this mold, and more […]

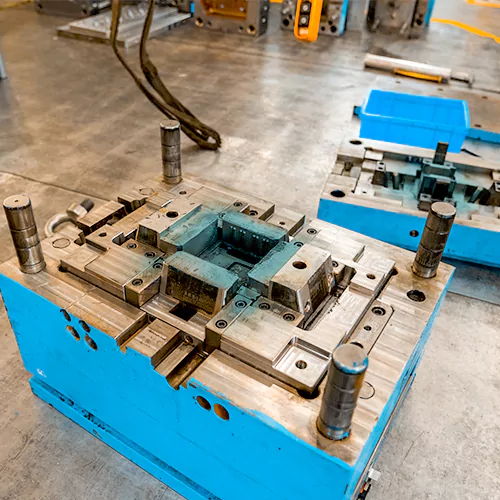

Principles of Selecting and Creating an Effective Mold Base

Are you wondering what a typical mold base is? It may appear to be a simple phenomenon. Precisely, a mold foundation is a pre-machined base that helps complete your mold per your requirements. However, when selecting, preparing, and using it – there’s more to a standard and effective mold base than just that. And to […]

8 Maintenance Methods to Enhance Mold Cavity Life

Did you know? Regular preventative maintenance of injection molding tools like mold cavities is important to effectively fulfill plastic injection molding demands. Hence, manufacturing plastic products using the mold cavity isn’t the end of your tasks as a machine operator. Instead, once you complete production work, maintaining the mold cavity is just as crucial as […]

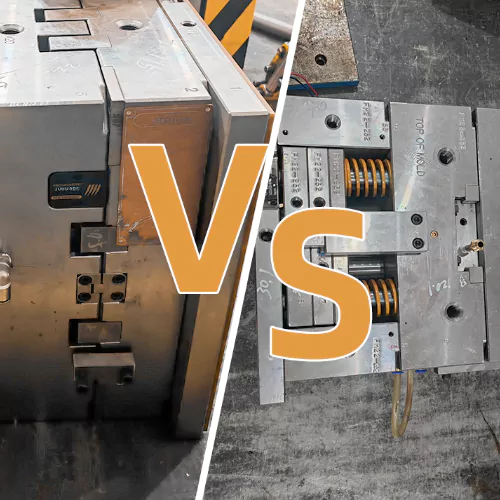

2 Plate Mold or 3 Plate Mold: The Difference

Typically, the decision to choose an injection mold depends on the type of product, its design, production volume, and budget. However, even after you have all this sorted, how do you know which mold is better: 2 plate mold or 3 plate mold? Don’t worry if you’re confused; this detailed guide will help you understand […]

Why is Mold Fabrication So Hard to Learn?

Mold fabrication is a critical process in the manufacturing industry, and it involves the creation of molds or dies that you use to produce a wide range of products. While mold fabricating is essential for making high-quality products, it can be a challenging skill to learn. So are you a beginner or intermediate professional in […]

Design Guide for Different Types of Industrial Molds

In today’s ever-growing manufacturing industry, industrial molds are widely used in various manufacturing processes, including plastic injection molding, die casting, and sheet metal forming. These molds help shape raw materials into desired products. Now in the modern-day manufacturing world comprising various advanced machines and tools, industrial molds are some common options many manufacturers and companies […]

The Ultimate Guide to Designing, Making, and Maintaining The Die Casting Mold

Did You Know? Grand View Research‘s report indicates that the global die-casting market was worth $33.94 billion in 2020 and is projected to experience a compound annual growth rate (CAGR) of 6.2% from 2021 to 2028. Notably, die casting mold manufacturing finds widespread use in multiple industries, encompassing automotive, aerospace, electronics, and consumer goods, among […]