The 101 of Plastic Molding Quality Control – A Detailed Guide

Plastic molding quality control is essential in plastic injection molding because it ensures that goods are perfect. It requires careful steps for planning, developing, designing, and making. The proper mold design method and the correct process planning ensure customers get high-quality plastic products that meet their needs. Precision production control helps stop and eliminate mistakes […]

The Causes and Solutions of Warping in Injection Molding

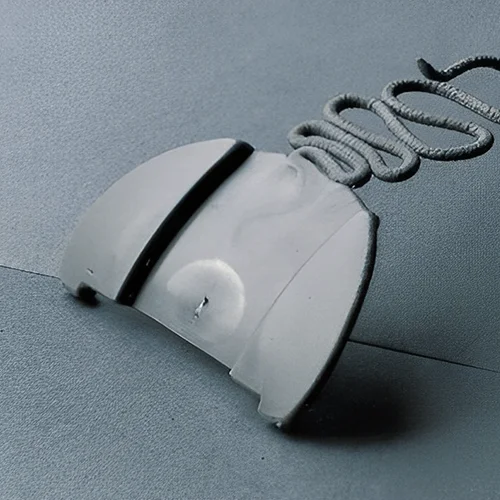

Warpage, the injection molders‘ nemesis! It’s a common problem, especially during the fine-tuning process. Now picture a part that should match the cavity but decides to deviate, resulting in a warped section. In this scenario, even non-experts can spot the bending or twisting. So what do you do in this situation? Simple: avoid unintentional bending […]

HDPE Injection Molding | Plastic Injection Molding Service

HDPE injection molding has become a game-changing technology in modern manufacturing, changing how many goods are made. This article gives a brief overview of HDPE molding. It talks about how precise, efficient, and essential it is to many different businesses. What is HDPE? High-density polyethylene (HDPE) is a highly crystalline non-polar thermoplastic resin with a […]

Injection Molding Nozzle – Types, Defects, and Characteristics of a Quality Nozzle

Injection molding is a popular and widely used way to make things. An injection molding nozzle is a key part of the ejector system at the bottom of the molding machine. Its main job is to move melted plastic from the barrel into the mold, a key part of making the end product. The mold’s […]

Vacuum Voids in Injection Molding: Unraveling The Most Common Injection Molding Defect

Although the plastics manufacturing business has been more productive thanks to plastic injection molding service, its finished products don’t always meet the client’s expectations. From lack of efficiency in managing the injection molding process to operating errors, production errors, and whatnot – different aspects of this production approach can lead to common injection molding defects. […]

Jetting in Injection Molding – Identifying the Cause and Troubleshooting the Defect

Jetting occurs in a molded component when molten material is injected into the mold cavity and starts solidifying before it fills the cavity. It is a type of distortion caused by this premature solidification. Furthermore, jetting is frequently visible as a squiggly line on the surface of the final component, typically leading from the original […]

Got Discoloration in Injection Molded Parts? Here’s How To Fit It!

Injection molding discoloration is a variation from the plastic’s base color. Overheating, contamination, and faulty production could all contribute to this faulty component. The degree to which a flaw in the part’s coloring due to thermal degradation is evident varies with the severity of the degradation. To avoid this problem, it’s important to have a […]

Flow Lines Defect in Injection Molding: Solving and Preventing a Common Injection Molding Defect

Due to its precision, several issues may arise throughout the injection molding process. The cosmetic or structural integrity of the part can be compromised by anything from operator error to flaws in the mold design. One common error manufacturers often face during this process is flow lines defect in injection molding. Now if you’re a […]

Analyzing The Occurrence of Injection Molding Weld Lines and Their Solutions

Injection molding weld lines refer to a line on an injection molded part that is generated where the two halves of the mold come together. As a result, the portion has a faint, perhaps undetectable line. This line does not normally impact the overall shape or dimensions of the item. Still, it can be seen […]

A Deep Analysis of Burn Marks in Injection Molding

“Burn marks” are a type of flaw in injection molded parts that manifest as a blackened edge near the very end of the cavity-filling process. Air that becomes trapped in the injection mold’s cavities causes burn marks. As the plastic was pumped into the mold, it compressed the air inside the cavities to the point […]